Sea glass comes in an amazingly wide range of colours and hues, but have you ever wondered how that glass got its colour, well here’s a little look at the science of colouring glass.

90% of glass is made from a standard mix of Silicon Dioxide (70%); Calcium Oxide (14%); Sodium Oxide (16%) percentages may vary slightly, with various trace elements added to provide the colour.

A number of materials, mostly metal compounds, are commonly used to colour glass, including cobalt, lead, uranium, copper and even gold.

A glass container’s colour was chosen to make the product more appealing, the same perfume or drink can sell for a premium in a sapphire blue bottle compared to a clear one.

These days, glass makers can precisely control the colour they wish to achieve, but centuries ago, it was coloured through random experiments, with varying degrees of success.

Over a millennium ago. Abu Musa Jabir ibn Hayyan, a Persian chemist, concocted dozens of recipes for colouring glass. He discovered that metal oxidation was the catalyst for colouring, earning him the title ‘The Father of Chemistry’.

Back in the day

After this discovery, colouring glass soon became a major industry. Firstly it was small bottles and ornaments, but soon, religious groups demanded custom coloured glass, and stained glass was born. However, there was a problem: Those gorgeous colours didn’t last for very long. Red in particular faded quickly. After a little more experimenting, craftsmen found that adding a little gold to red preserved the color, a method that’s still used today.

Modern glass colouring

Today, manufacturers have precise, tried and tested recipes. You still have to add metal for the brightest, longest-lasting colours. Sulfide and powdered oxides are the most common. To create yellow, you add cadmium sulfide; red still requires gold chloride; a blue/violet hue needs cobalt oxide; purple needs manganese dioxide; pure violet requires nickel oxide; and emerald green calls for chromic oxide.

These are just a few of the options available. Additional colours can include fluorescent yellows and greens, ambers, whites and browns.

Some of the main colours

AQUA, AQUAMARINE glass, also known as SEAFOAM is a “natural” result of the iron impurities found in most sands (Silicon Dioxide). It is very rare, if not unknown, for sand not to contain some traces of iron. Sand deposits with very low iron content are a highly valued commodity.

Aqua glass is the result of sand which had a relatively low amount of iron, and therefore didn’t require the addition of decolourizing agents (see ‘Clear Glass’ below).

Higher levels of iron produce darker greens, black glass, and even amber. Natural aqua glass was often called “green glass,” “bottle glass,” or “bottle glass green” by glass makers

COLOURLESS glass is rarely absolutely colourless. It will usually have very faint tints of pink, amber, grayish green, gray, or grayish blue. These faint colours can be seen easiest when looking through a thick piece of glass, i.e., side on. Colourless glass is usually produced by using the purest sand source possible and by adding “decolourizing agents” to offset the residual iron impurities. Commonly used for this were manganese dioxide, selenium dioxide (usually together with cobalt oxide), antimony and arsenic oxide – which is also used as a stabilizer of selenium in decolourizing glass – or some combination of these compounds

One result of the use of Manganese Dioxide is that glass decolourised using this compound will, upon exposure to sunlight, turn a light pink or lavender to a moderately dark amethyst or even a deep purple depending on the amount of manganese in the glass mix and amount of ultraviolet that it is exposed to..

OPAQUE WHITE glass – commonly called milk glass but sometimes called opal or white glass – was produced by the addition of tin or zinc oxide, fluorides (fluorspar), and phosphates. It was also created by adding calcium and phosphate rich animal horns, bones, and even “bat guano” to the glass batch.

GREEN glass. There are probably more different shades of green to be found than any other colour. It rivals the multitude of amber glass variations which can grade into various greens. The different greens were formed by a myriad of different colouring agents, impurities, and/or glass making processes. Iron, chromium, and copper all produce different green glass. Chromium oxide will produce yellowish green under oxidizing conditions and emerald green under certain conditions in the glass furnace. Combinations such as cobalt mixed with chromium will produce blue-green/teal glass

AMBER glass is very common and like the greens above, amber colours were a result of the natural impurities in glass (i.e., iron & manganese) as well as from colour additives such as nickel, sulfur, black lead and in particular carbon, which was added to the glass batch in the form of coal, charcoal, or even wood chips.

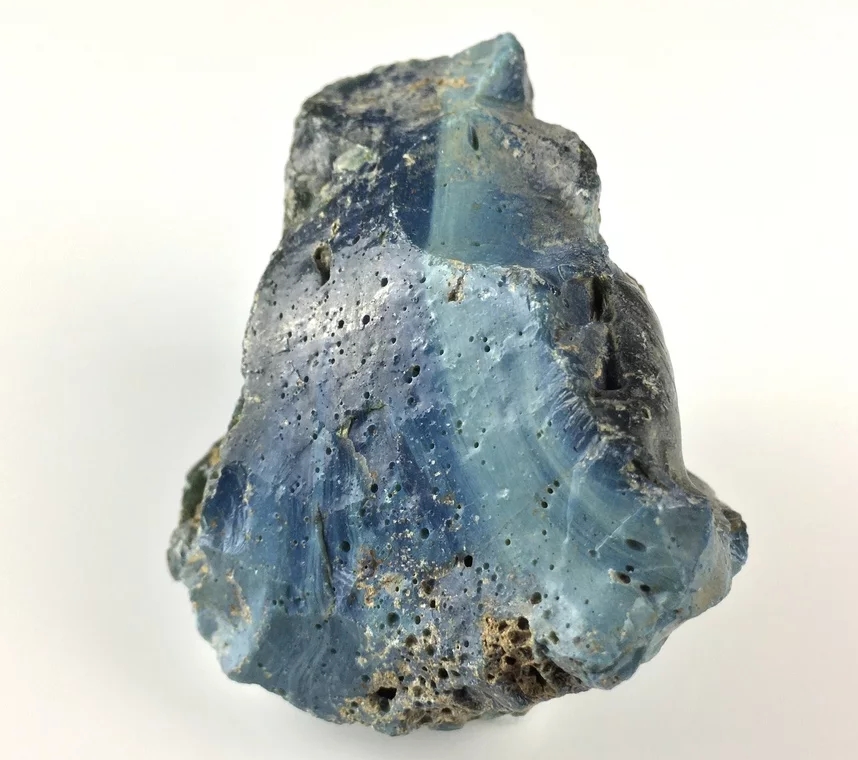

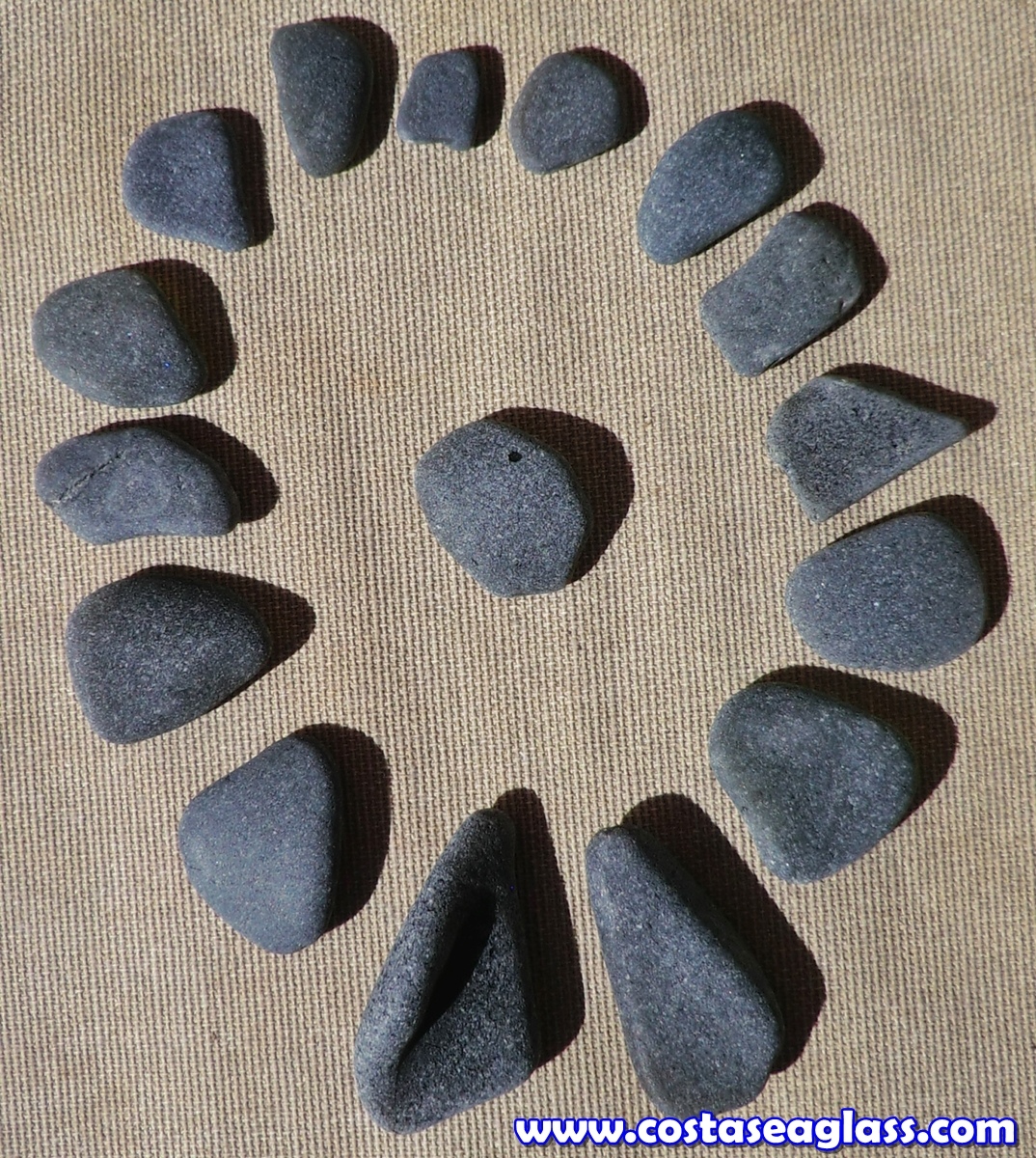

BLUE glass, from moderate to intense, is usually produced with the addition of the colouring agent cobalt oxide to the glass. Copper can also produce types of blue glass depending on the batch ingredients and temperatures used.

PURPLE, AMETHYST and RED were usually a result of glass that was coloured with nickel or manganese oxides and sometimes selenium, with true red usually a result of the use of an oxide of gold. As noted in the colorless glass description above, small amounts of manganese dioxide was used as a decolourizer to offset the iron impurities present in virtually all sands. This colourless glass will variably turn amethyst upon long term exposure to sunlight. With larger concentrations of these substances in the glass batch amethyst to purple glass is purposefully created

BLACK glass is a form of green glass which is so deep a colour as to appear black in reflected light and even in direct light This strong and resilient glass was also a colour that offered the most protection to the contents from the effects of direct light. Most black glass is actually a very dark olive green or olive amber. These types of black glass were the result of the same impurities or colouring agents as the olive colors, usually high iron concentrations but also other substances including carbon (from various sources including ashes and coal clinkers), copper with iron, and magnesia.

Well I hope you found this article informative. I will be looking in more detail at individual colours in the near future.

See also: BLACK GLASS